Rethinking Dust Valves

ATEX compliance in dust handling is often discussed in terms of labels and zones. In practice, the real challenge starts much earlier: understanding whether a dust valve can actually prevent flame and pressure propagation during an explosion.

Key engineering considerations

Parameters such as MESG, MIE and MIT define the real safety margins of a dust handling or filter system. If these are not aligned with the valve design, certification alone can create a false sense of security. Especially when a dust valve is expected to function as part of a certified Protection System, sealing quality, flame-arresting capability and pressure-shock resistance become critical engineering criteria.

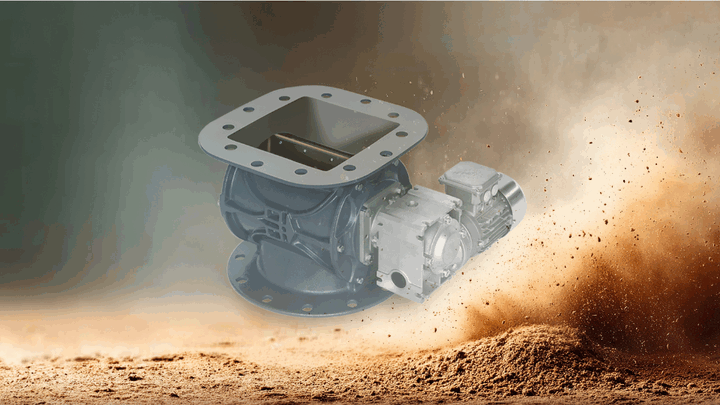

Using our extensive process knowledge and vast experience in rotary valves, we have documented key engineering considerations in a technical white paper on dust valve design. The white paper explains how explosion parameters translate into concrete design choices, covering efficiency through drivetrain design, leakage control, internal ATEX Zone 20 requirements, and system-level explosion protection.

For system integrators and OEMs working with explosive dusts, this knowledge is essential for both compliance and risk mitigation. If ATEX, MESG or explosion compartmentalisation plays a role in your projects, we are happy to share the white paper.

Contact marketing@tbma.com

TBMA are specialists in the design and supply of components and systems for bulk solids handling. Our extensive range of high quality processing equipment is suitable for handling powders and granules with proven reliability in practice in a variety of processing industries. The highly qualified and experienced TBMA staff are well able to translate your requirements into the right execution and application of our components. We also offer the design and execution of complete projects, thus providing you with an efficient, reliable and sustainable solution for your process.

How can we help you?