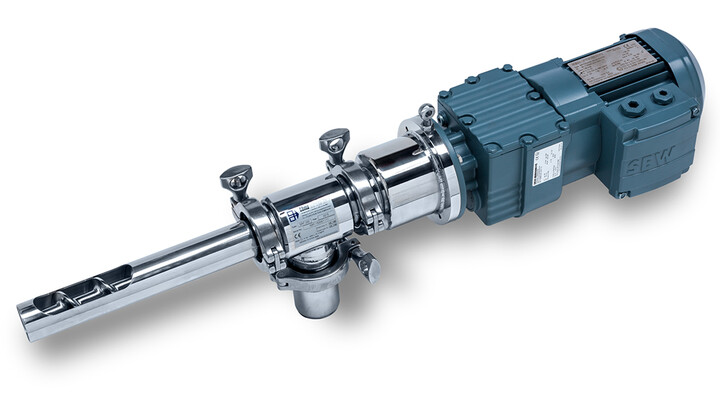

SRF sampler

- Automatic sampler

- Hygienic design for high-end applications

- Quick-clean

Adjustable sample size

The SRF high-end automatic sampler can be used for sampling powders, granules or flakes out of down spouts lines or hoppers. Due to the use of a screw the sample size is adjustable. Also, poorly flowing products are easy to process.

The SRF consists of a 2” stainless steel 304 tube with tri-clamp connections for mounting to the drive. The inner and outer tube are divided by a Delrin tube. The sampler is easy demountable: by using tri-clamp connections the complete sampler can be easily taken out for inspection and cleaning as a whole or just partly. The outer tube can be equipped with a connection piece or directly welded into the hopper.

The precision polished finish makes this sampler the right fit for high-end applications in the food and dairy industry. The SRF is internal ATEX 2014/34/EU certified, external ATEX 2014/34/EU certified is optional.

Applications

Working principle

When starting the sequence, the auger will first turn backwards for an adjustable period to remove any possible sample material from the previously taken sample. Then it takes the actual sample during an adjustable period, depending on the required size of the sample. Gravity causes the sample to drop down into the sample jar.

SRF samplers can be supplied including a control unit, consisting of a cabinet with Siemens Logo PLC and fuses, switches, motor protector and frequency converter. The cabinet is internally wired and tested and standard suitable for a non-classified zone. This control unit is optionally available conforming to ATEX 2014/34/EU.

Features

- Suitable for powders, granules, and flakes

- Adjustable sample size

- Product contact parts stainless steel 316 polished Ra<0,8

- Product contact parts food approved

- Outside stainless-steel parts mirror polished

- Tri-clamp connections

- Easy demountable for easy cleaning

- Conforming to ATEX 2014/34/EU (optional)

Options

- Connection piece on outer tube (multiple sizes available)

- Control unit

- Extended screw

- End bearing

- Holder with sample jar (stainless steel or plastic)

- Niflon coating for sticky products

Downloads

Brochure Samplers View