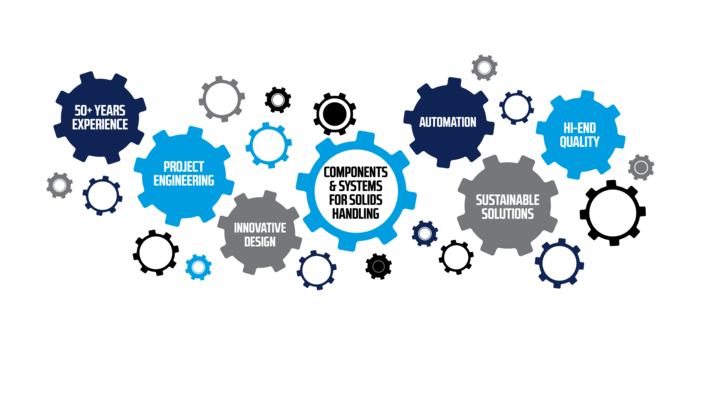

Solutions beyond bulk handling

At TBMA we have more than half a century of experience in bulk material technology and process engineering. Our components and systems for the processing of dry, solid substances can be found in process installations all over the world.

History

TBMA (Technical Bureau for Mechanization and Automation) was founded in 1967 under the leadership of the father of Bart Houben, managing director until the end of 2023. Father Houben started the company by importing the English Westinghouse Derion rotary valves and supplying pneumatic transport systems. In 1992, after the death of their father, the brothers Bart and Frits Houben took over the management of the company.

Under their care, TBMA has continued to grow into today’s international player in the field of mechanisation and automation of industrial processes.

Components & systems

We specialise in the design and supply of components and pneumatic transport systems for the processing of dry bulk goods. Our extensive range of high-quality equipment is suitable for handling powders and granules with proven reliability in practice in various industries.

Our product overview includes solutions for dosing, storage, big-bag filling or unloading, bag emptying, pneumatic or mechanical conveying, mixing, weighing, sampling, etc., suitable for demanding, hygienic and/or heavy, industrial applications.

Creative and sustainable

Our specialty lies primarily in creating solutions for the transport of powders and granulates before, during and after processing processes.

With innovative, creative and sustainable components and systems, we strive for processes that are well manageable and clean. Efficient, safe and less stressful systems ensure a safe working environment, energy saving and the reduction of environmentally harmful processes.

Customised engineering

The qualified and experienced TBMA employees can translate your requests into the correct execution and application of our components. We also gladly use our expertise if you need something out of the ordinary.

Moreover, we take care of the design and implementation of complete projects, whereby we offer you an efficient, reliable and sustainable solution for your process. In addition, we are known for our experience in the field of automation and mechanisation of complete installations.

Expertise and innovation

TBMA components and systems have been used for more than half a century in the food, dairy, animal feed, chemical and mineral industries and in value added logistics.

With our many years of practical experience in combination with inventiveness and flexibility we can offer you sustainable solutions for an optimal reliable, profitable and high-quality production process. In our own test room we can also test the proposed technical solution for your product in advance.

Our know-how and innovative mind-set are of decisive importance for many clients when choosing TBMA as their partner.

Solutions beyond bulk handling

VCA** certified

TBMA is VCA** (2 star) certified. For you as a customer, this means that you can be confident that TBMA meets the necessary safety requirements for “assembling, installing, commissioning and maintaining systems and components for handling and transporting substances”. And we are quite proud of that!

The purpose of VCA is to identify and control the safety and health risks for the employees in the workplace. VCA** moves to the next level: this is intended for subcontracting companies and is aimed at the total structure (policy, improvement management and organisation) that is used to record these HSE matters.

TBMA has been VCA** certified since 2013. The Safety Management System of TBMA Europe BV was re-audited by SGS Belgium NV in November 2025 and approved for the VGM Checklist Contractors (VCA**) Rev. 2017/6.0/**. The new certificate is valid until 21 July 2027.

Machevo | EHEDG membership

The Machevo & Bulk Association has been the network for the Dutch and Belgium process industry for more than 55 years and the trade association for producers, suppliers and exhibitors of process installations, process engineering, process automation and process equipment in the (petro) chemical, food, pharmaceutical and biotechnology industries. machevo.nl/

The main goal of the EHEDG (European Hygienic Engineering & Design Group) is to improve the promotion of safe food through hygienic engineering and design in all aspects of food production. The organization was established in 1989 as a non-profit consortium of equipment manufacturers, food producers, suppliers to the food industry, research institutes and universities, public health authorities and government organisations. ehedg.org