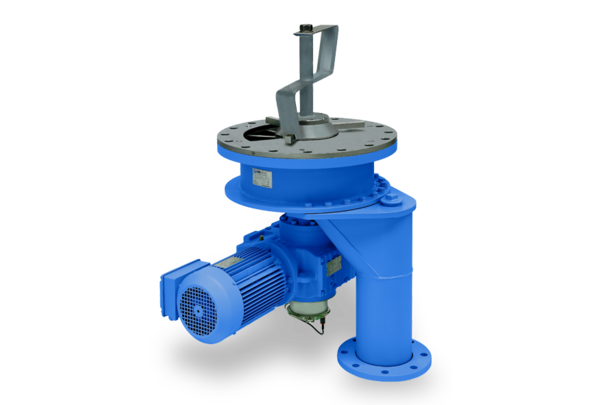

HZ Horizontal valve

- Accurate and continuous dosing

- 24/7 heavy industrial applications

- Extremely robust construction with vertically positioned rotor

- Special discharge agitator for poorly flowing products

Introduction

The HZ horizontal rotary valves by TBMA are used for accurate and continuous dosing of products such as coal, barite and bentonite. The HZ valve has an extremely robust construction and a large inlet with a relatively small rotor volume. The vertical agitator of the valve ensures that the valve works with an exact 100% filing degree.

The HZ valve can be used in combination with a pressure vessel in a pneumatic transport system with a very accurate dosage.

Applications

In brief

- Large inlet opening with vertically positioned rotor

- Complete emptying of the rotor pockets

- Very accurate and repeatable dosing characteristics

- Special discharge agitator for poorly flowing products

- 100% filling degree

- Pulsation-free product flow

- Dosage linear with the speed

Specifications

- Flange sizes: DN150 – DN700

- Flanges: drilled in accordance with PN10

- Rotor volume: up to 100.000 ltr/hr

- Explosion proof: up to 10 barg

Executions

- Corrosion resistant version for chemically aggressive products

- Abrasian resistant version for abrasive products

- Specially coated version for sticky products

- Alternative materials (steel, stainless steel, Hastelloy, etc.)

Drives

- Geared motor with closed chain trainsmission (type HZK)

- Slip-on gear with direct drive (type HZMP)

Options

- Rotation detection

- Deviating flange bores

- Pulsating air injection system

Industries

Curious when to use the above system? Have a look at our selection of industries for a suitable application of this system and of our other products.

Looking for a more specific industry and/or application? We are happy to take on the challenge! Contact us at sales@tbma.com.

TBMA are specialists in the design and supply of components and systems for bulk solids handling. Our extensive range of high quality processing equipment is suitable for handling powders and granules with proven reliability in practice in a variety of processing industries. The highly qualified and experienced TBMA staff are well able to translate your requirements into the right execution and application of our components. We also offer the design and execution of complete projects, thus providing you with an efficient, reliable and sustainable solution for your process.

How can we help you?