SPV sampler

- Automatic sampler

- Free-flowing products

- For use in down spouts

Free flowing powders

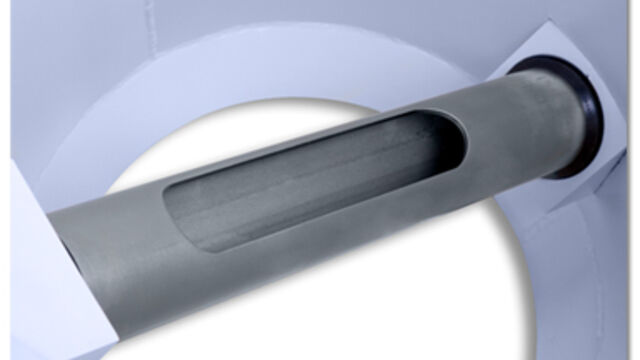

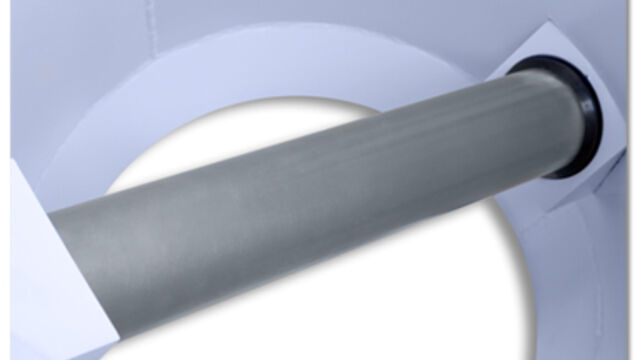

The SPV automatic sampler can be used for sampling free flowing powders, granules or flakes out of down spouts. It consists of a pipe section matching the diameter of the conveying line with a permanent, inclined sampling tube.

Due to the angle of the tube, the sampled product must be free flowing. The tube has a longitudinal sample slot on one side. When not in use, the slot is facing down.

Applications

Working principle

When the sampler is activated, the pneumatic torque cylinder rotates the sample tube until the sample slot faces upwards. (1)

Material enters the sampler through the sample slot and gravity causes the sample to slide down into the sample jar. After sampling, the sample tube is rotated back until the sample opening is facing down. (2)

Material will pass the sample tube without being extracted.

SPV samplers can be supplied including a control unit, consisting of a cabinet with Siemens Logo PLC and fuses, switches, motor protector and frequency converter. The cabinet is internally wired and tested and standard suitable for a non-classified zone.

Features

- Suitable for free flowing powders, granules, and flakes

- Product contact parts food approved

Options

- Control unit

- Sample jar (stainless steel or plastic)

- Niflon coating for sticky products

Downloads

Brochure Samplers View

Industries

Curious when to use the above system? Have a look at our selection of industries for a suitable application of this system and of our other products.

Looking for a more specific industry and/or application? We are happy to take on the challenge! Contact us at sales@tbma.com.

TBMA are specialists in the design and supply of components and systems for bulk solids handling. Our extensive range of high quality processing equipment is suitable for handling powders and granules with proven reliability in practice in a variety of processing industries. The highly qualified and experienced TBMA staff are well able to translate your requirements into the right execution and application of our components. We also offer the design and execution of complete projects, thus providing you with an efficient, reliable and sustainable solution for your process.

How can we help you?