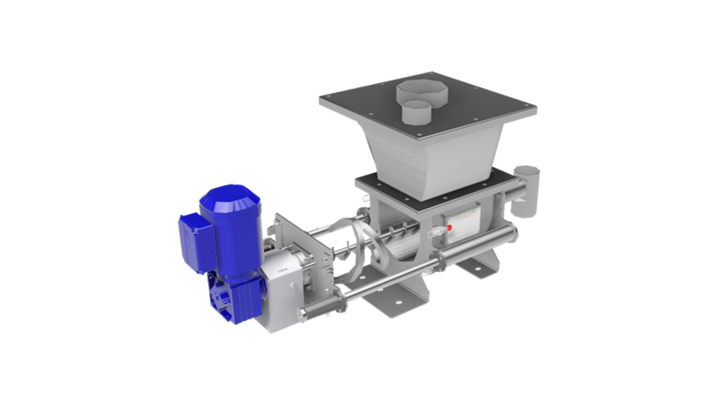

PCF centre feeder

The PCF center feeder is unique due to the combination of a central dosing screw and a concentric agitator that slowly rotates around the screw.

PCF feeder

The agitator ensures that the product maintains a consistent bulk density and that the dosing screw is evenly filled, enabling highly accurate volumetric dosing — even for poorly flowing products.

In addition, this design creates a larger opening to the hopper, significantly reducing the risk of bridging. Because the agitator rotates around the screw, there is no risk of bridging between the agitator and the dosing screw — a phenomenon often seen in conventional dosing units.

The dosing screw and agitator are driven by a single motor with a special gearbox. The agitator rotates very slowly to prevent product damage, but always in a fixed ratio to the dosing screw.

For more information: sales@tbma.com (NL) or sales@tbma.be (BE)

Features

- Universal unit, suitable for use in nearly all industries: chemicals, food, minerals, etc.

- Long service life and low maintenance requirements

- Excellent price/performance ratio

- Extremely robust design, also suitable for heavy industrial applications

- Product contact parts made of stainless steel 304 as standard, optionally available in stainless steel 316L

- Standard internal and external Viwateq finish; internal weld grinding optional

- Special shaft seals available, including options with constant overpressure and air purging

- Specially developed, high-quality gearbox for the concentric drive of the synchronously slow-rotating agitator

- Easily upgradable to gravimetric control

- No “black box” control but an open PLC system, perfectly integrable into the production line control

- Quick-clean version available (optional)