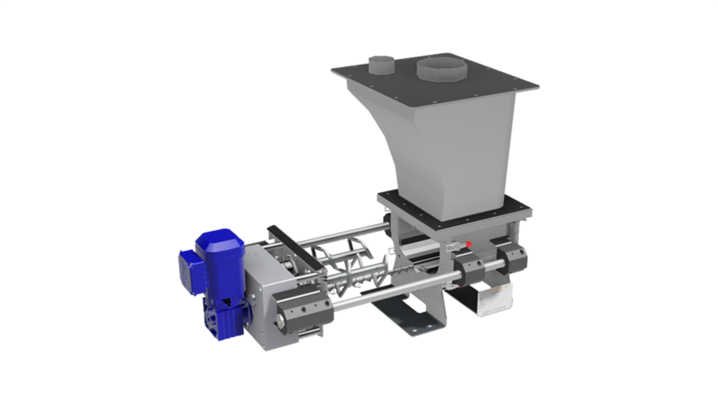

PTF triple feeder

The PTF triple feeder is unique due to the combination of a standard central drive with a pre-reduction gearbox.

PTF triple feeder

The triple-stage distribution gearbox ensures that a single drive can operate both the dosing screw and the two agitator shafts. The dosing screw and the two agitator arms rotate at different speeds, but always in a fixed ratio.

The agitators rotate very slowly to prevent product damage and rotate around the dosing screw. This design ensures that the dosing screw is optimally filled with a constant bulk density, guaranteeing highly accurate volumetric dosing.

The PTF is particularly suitable for very poorly flowing products. Due to the large dosing chamber, the opening to the hopper is very wide, minimizing or virtually eliminating the risk of bridging above the dosing chamber. Because the agitators rotate around the dosing screw, there is no risk of bridging between the agitators and the dosing screw — a phenomenon often seen in conventional dosing units.

For more information: sales@tbma.com (NL) or sales@tbma.be (BE)

Features

- Universal unit, suitable for use in almost all industries: food, chemicals, pharmaceuticals, biomass, plastics, paper, pet food, cement, sugar, etc.

- Highly accurate dosing, especially for poorly flowing, bridging products

- Long service life and low maintenance requirements

- Excellent price/performance ratio

- Extremely robust design, also suitable for heavy industrial applications

- Product contact parts made of stainless steel 304 as standard, optionally available in stainless steel 316L

- Special shaft seals available, including options with constant overpressure and air purging

- Specially developed, high-quality gearbox for the synchronous drive of the dosing screw and the two agitators with a single electric motor

- Easily upgradable to gravimetric control

- Quick-clean version available (optional)