Aquafeed

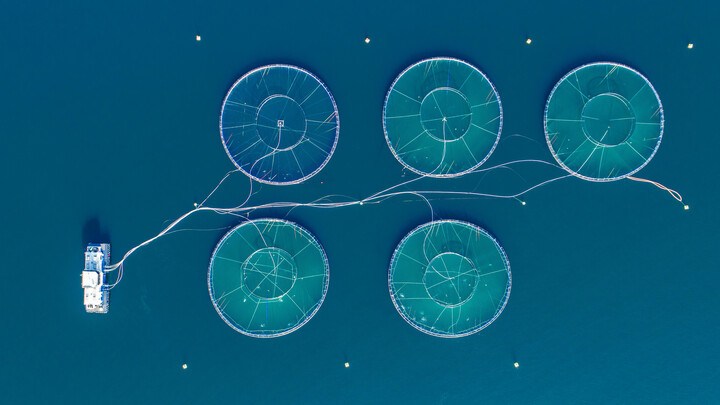

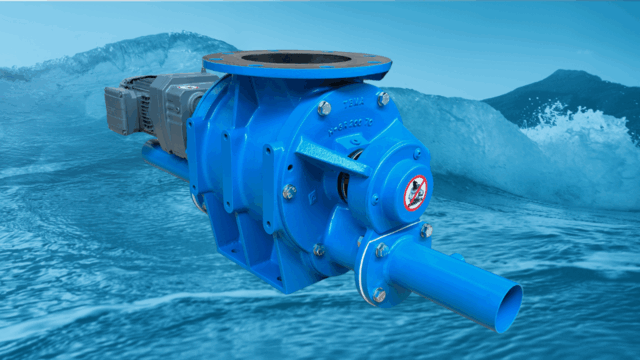

With the increasing growth of saltwater fish farms, the demand for automatic feeding systems is also increasing. TBMA H-GR blowing seals are widely used for the transport of fish feed on feeding barges. They are equipped with an adapted rotor, ensuring that the fish feed is transported and efficiently dosed with minimal damage to the feed itself.

New standard in Aquafeed

TBMA have redesigned their H-GRD blowing seal, dedicated to handling fish feed on feeding barges for open sea fish farming. Barge builders have to deal with specific requirements for the feeding systems, such as limited space and an isolated, salty environment. So, how could we help them with a smart solution valve?

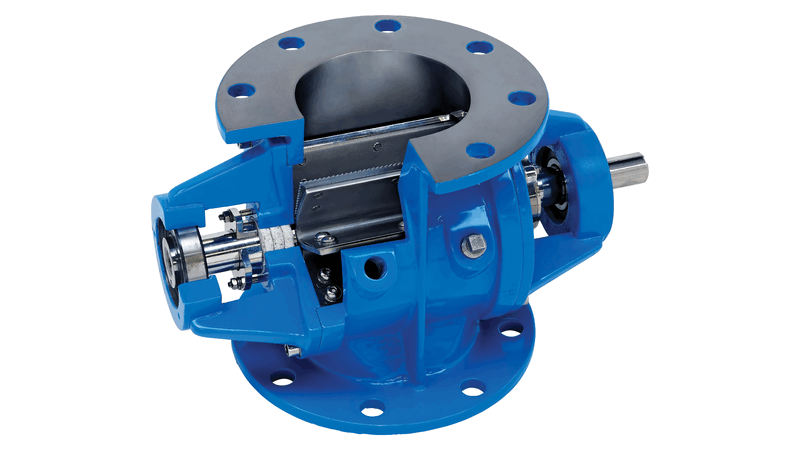

The H-GRD of itself already is a robust and reliable valve that offers efficient dosing. Most important for aquafeed, its gentle handling causes minimal damage to the fish feed and therefore minimal water pollution. As a result, the ROI of the valve is very favourable.

For the redesign, we mounted a direct in-line drive and consequently reduced the number of parts. As a result, maintenance is even easier than before and less spare parts are required. Moreover, the valve has a smaller installation size. Triple advantage!

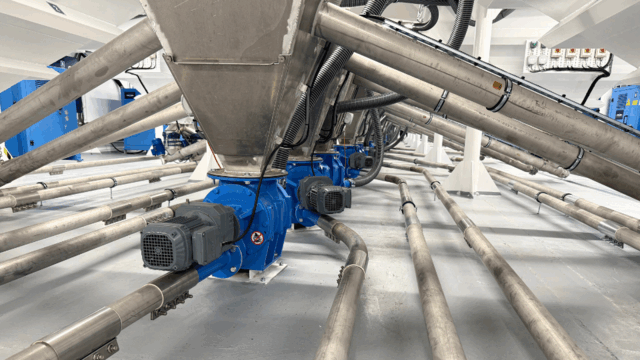

We are excited that our customers have enthusiastically welcomed the new design: the valves are already being used on the largest barge built so far. Read more about Seaworthy rotary valves for Aquafeed

The upgraded H-GRD will be on display at the Aqua Nor (stand B-227 | 19-21 August | Trondheim (NL)), Powtech (stand H12-337 | 23-25 September | Nuremberg (DE)) and Solids Rotterdam (stand G05 | 1-2 October | Rotterdam (NL)).

Preventing feed degradation

The aquafeed industry plays a vital role in supporting global aquaculture, providing essential nutrition to farmed fish and other aquatic species. It encompasses the production and distribution of specialised feeds tailored to meet the nutritional needs of various aquatic organisms. Aquafeed formulations often consist of a mix of protein sources, vitamins, minerals, and other additives to promote growth, health, and optimal performance.

With the growing demand for seafood, the aquafeed industry has been expanding rapidly, driven by advancements in feed technology and increasing awareness of sustainable aquaculture practices. Continuous innovation and research are crucial for developing (cost) efficient and eco-friendly feed solutions to meet the industry's evolving demands. When it comes to the feeding equipment, these demands include minimal feed degradation and water pollution.

Feeding barges

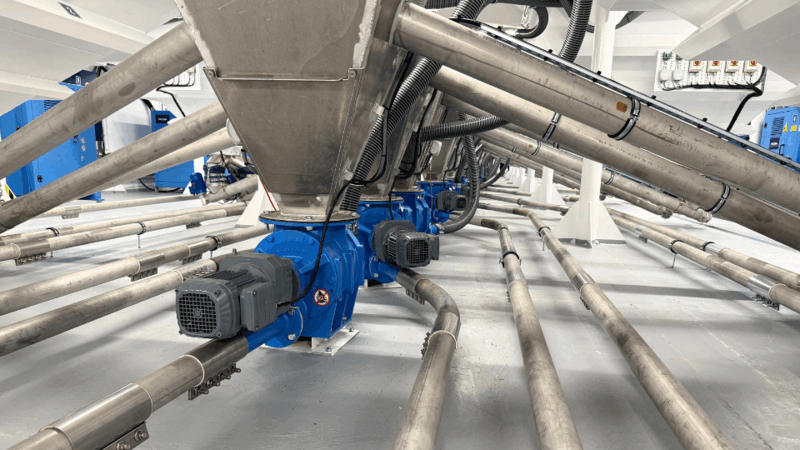

The increasing growth of saltwater fish farms consequently raises the demand for automatic feeding systems at e.g. feeding barges. The expensive high-quality feed must end up in the water undamaged. Every single pellet must be handled gently to avoid breakage and crumbling. The TBMA HGRD200 blow-through rotary valves are being used to discharge and dose the feed efficiently from the hopper into the feed transport pipeline. These rotary valves are equipped with an adapted rotor, ensuring that the product is dosed and transported with minimal damage.

The valves are of a robust and reliable design and the easy demountable execution guarantees quick (dis)assembly and easy maintenance. The reliability of the valve and the careful handling of the fish feed ensure a very favourable ROI (return on investment) and minimal water pollution.

Video: The Perfect Serve

Blow-through rotary valves

TBMA H-GR blowing seals have been used by major feeding barge manufacturers for many years. This picture shows a fine collection of 16 rotary valves ready for shipment to JT electric (now part of GroAqua) in the Faroe Islands. When designing their custom made feeding barges for fish farming, JT electric use TBMA rotary valves for the dosing and transport of the fish food.

“We use TBMA rotary valves because the tests we performed on the valves proved them to be of good quality. Also we appreciate the cooperation with the dedicated and skilled TBMA sales team. In the process from the first contact, our relationship with TBMA has grown stronger and closer”, states Ólavur Thomsen, Project Manager at GroAqua (formerly JT electric).