Activated carbon system for biological water treatment

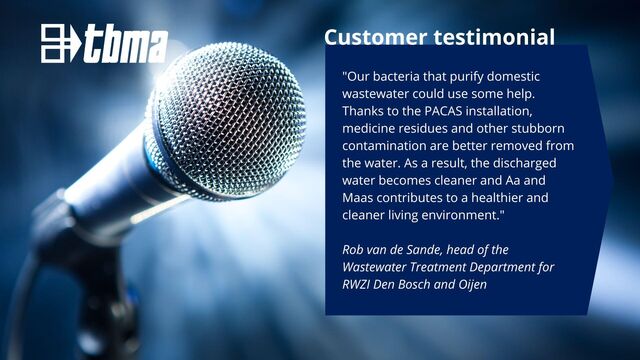

Purification plants ensure that the wastewater of Dutch households is cleaned. This is increasingly happening with biological processes. Bacteria clean up most of the pollution, but activated carbon is needed for drug residues.

TBMA has supplied a so-called PACAS installation for this purpose.

Biological purification

After cleaning, the wastewater is discharged back into the surface water, so it must be as clean as possible. Bacteria 'eat' the water clean and ensure that traces of urine, faeces and washing water are cleaned up. This becomes more difficult with drug residues: these mostly chemical substances cannot be removed by bacteria. One of the ways to remove these residues is to add powdered activated carbon to the water to be purified.

Aa and Maas Water Board | Mid 2021, TBMA was asked by main contractor GMB Civiel to participate in a project for a biological sewage treatment plant (RWZI) of the Aa en Maas Water Board. This water board in the northeast of the Dutch province of North Brabant includes the catchment area of the Aa and its tributaries, the North Brabant part of the Meuse basin and therefore also the Brabant part of the Peel.

PACAS installation

The aim of the project was to improve the quality of the purified wastewater. To this end, an extra component was added to the total cleaning process: a PACAS installation. PACAS stands for Powdered Activated Carbon in Activated Sludge, or powdered activated carbon that is added to the activated sludge system of a sewage treatment plant. The very fine structure and large surface area of the powdered carbon ensure that drug residues can bind well to it, after which they can be largely removed from the water.

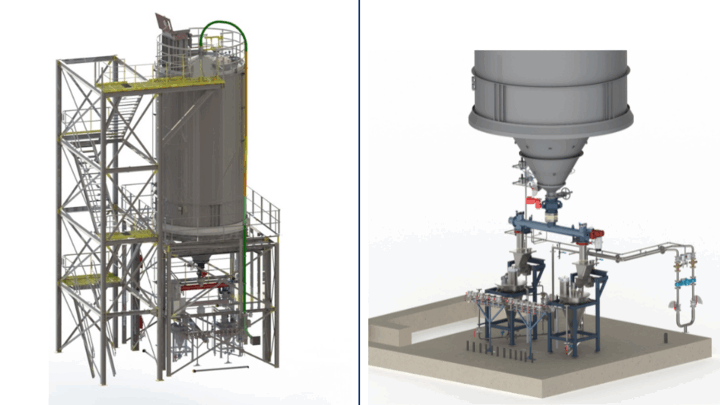

The total contract to GMB Civiel included the dry powder storage and processing and the transport of the slurry to the purification tanks. TBMA carried out the detailed engineering and delivery of the PACAS installation, in accordance with the specifications drawn up. In other words: bulk solids technology meets civil engineering.

Storage silo

The powdered activated carbon is stored in an 85m³ silo. This silo is equipped with instruments to detect possible heating in the activated carbon and safety features to limit the consequences of a possible dust explosion as much as possible. Extra attention has been paid to the smooth release of the powder. The system around the silo is set up in such a way that signals from this system inform the control room in time that a new supply of activated carbon is needed.

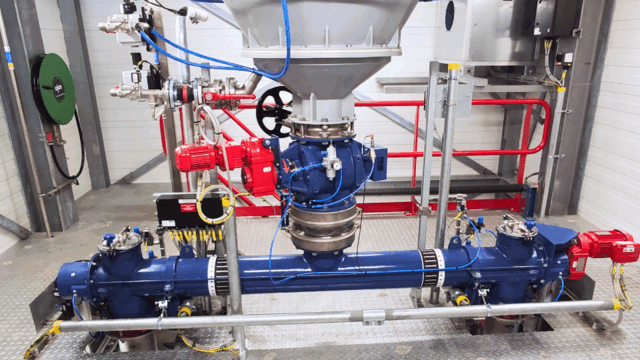

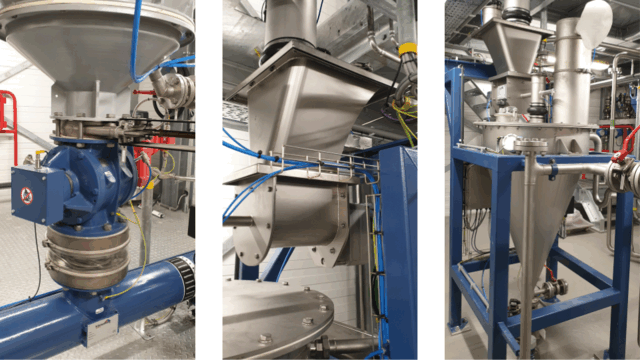

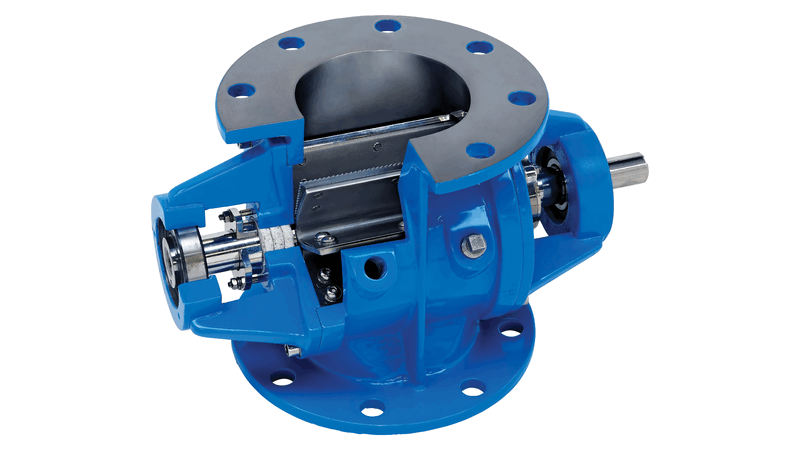

The discharging of the activated carbon to the process part of the installation takes place via a TBMA ATEX certified rotary valve with a screw conveyor underneath, which can rotate both left and right. The valve also acts as an explosion lock between the silo and the rest of the process equipment.

Dosing

The screw conveyor operates two loss-in-weight (LIW) feeders arranged in parallel. These consist of a storage hopper with a small dosing screw at the bottom. After receiving an 'empty' signal from one of the LIW feeders, the valve automatically discharges activated carbon powder from the silo and into the screw, which then fills the feeder. The rotation speed of the dosing screw is then continuously adjusted by the signal from the feeder's system to achieve the set feed rate.

Slurry

A vortex vessel is mounted underneath the outlet of each LIW feeder. The activated carbon falls into the middle of the vessel, which is internally sprayed with service water during the process. The slurry that is created in this way is sucked in by an ejector and pumped to dosing points on the aeration tanks of the water treatment plant. There, the slurry is mixed with the waste water, after which the activated carbon can get to work.

Fully automatic

The PACAS installation for the biological sewage treatment plant at Oijen was completed at the end of 2022. The entire installation runs fully automatically with monitoring from the central control room. Variable signals from flow meters and weighing systems, among other things, together with other process messages from the dosing system are communicated to the control room via a BUS system.

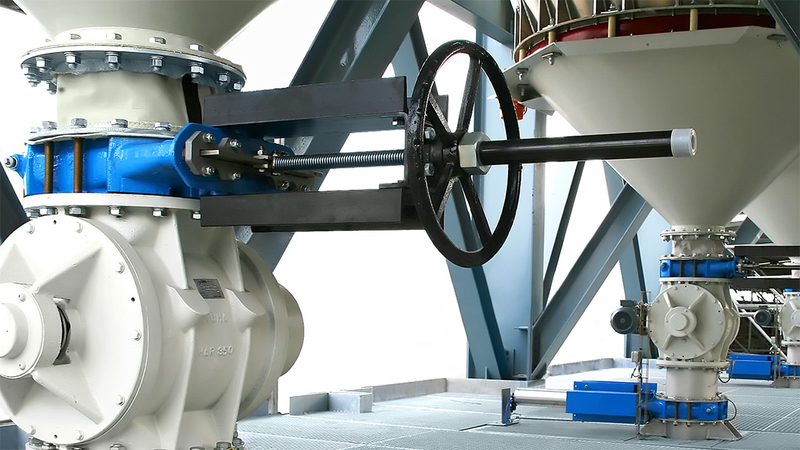

Maintenance has also been considered: a manually operated slide valve has been mounted under the silo, allowing periodic maintenance of the underlying system without emptying the silo.

Full-service | In addition to the engineering, TBMA also supplied and mounted the components and assisted in setting up the installation. The PACAS technique for removing drug residues will be rolled out further at other water treatment plants in the coming years. In fact, in Q4 of 2023, the same installation has been completed at the RWZI Dinther for the Aa and Maas Water Board.