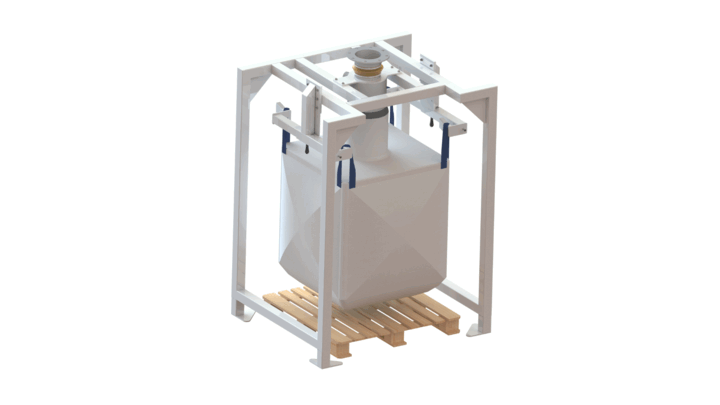

Type VB

Economical solution for big-bag filling

VB | Economical solution

The VB filling machine consists of a robust steel supporting construction with four uprights, has a minimal number of moving parts and is suitable for various types of big-bags.

The stainless steel, double-walled filling spout is equipped with a suction connection and Vollenda clamp, ensuring efficient filling and venting. Specially shaped bag suspension hooks facilitate a simple drive-off removal of the filled big-bags.