Seaworthy rotary valves for Aquafeed

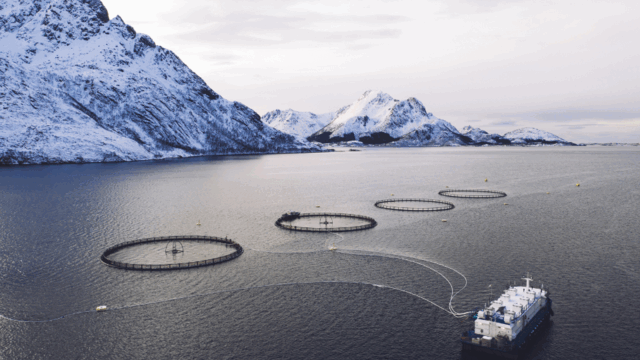

The global aquaculture industry has been growing for years. In the deep fjords of Northern Europe, Canada, and Chile, large floating fish farms can be found, made up of round net pens and a barge. TBMA’s rotary valves ensure the accurate dosing and transport of the delicate fish feed from the ship to the pens. And that’s not where it ends—when you look closely, we serve almost the entire aquafeed chain.

Opportunities across the entire aquafeed chain

Rotary valves are used for dosing and transporting raw materials and finished products in powder or pellet form. Like in the animal feed industry, where TBMA valves have been used for decades in the storage and production of raw materials, premixes, and granular end products like fish feed pellets. In addition to components such as valves and diverter valves, TBMA also supplies pneumatic conveying systems. This specific knowledge and experience has proven to be of great added value in the aquafeed industry.

From feeding barge to fish pen | Open-water fish farms typically consist of several large, round net pens and a (feeding) barge. These barges generally remain at sea. Alongside storage, dosing, and feed conveying systems, they also house crew quarters and a control room to monitor operations. The fish feed is delivered by a supply vessel.

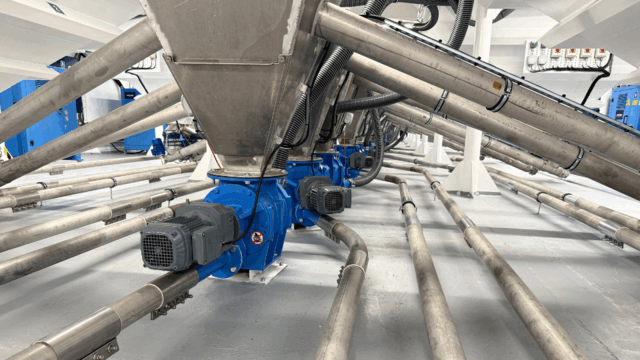

On the barges, the feed is stored in large silos and pneumatically conveyed to the pens. A screw conveyor under each silo fills a smaller hopper. Installed below the hopper is a blow-through rotary valve that, thanks to its design, prevents damage to the expensive and delicate feed. That might sound simple, but the operating environment is far from standard. The offshore location presents a remote, moist, and salty setting. The feed is slightly oily and becomes sticky when exposed to moisture.

Feeding picky salmon

When producing feed for farmed salmon, the right mix of ingredients is essential for optimal growth and health. Salmon feed combines both animal and plant-based ingredients with additives. Examples include fishmeal and fish oil (e.g., anchovies or sardines), vegetable proteins (e.g., peas or soy), grains or starches (e.g., wheat, corn, or potatoes), fruits and vegetables, and supplements like vitamins, minerals, and prebiotics. Nutritional needs can vary depending on the salmon's life stage.

In practice, salmon also have specific preferences for how their feed is served: it must be sprinkled from above into the water. Therefore, the feed comes in semi-aerated pellet form. Moreover, they only eat whole pellets; they turn their noses up at broken pieces.

Handle with care

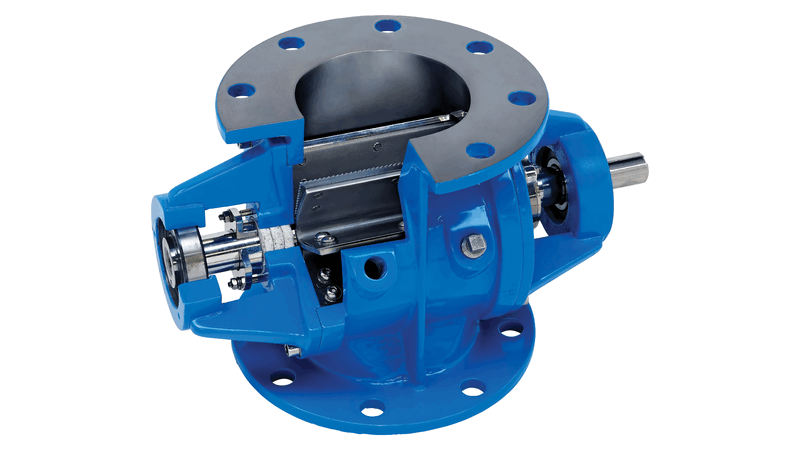

The ingredients, production, and logistics of delivering the feed to the pens make it a costly product. For the picky fish - and out of ecological responsibility to minimize water pollution - it is essential to avoid feed degradation. The combination of a remote offshore environment and expensive feed calls for a smart dosing solution. The H-GRD blow-through rotary valve is perfectly suited for the task and has proven its value over the years. TBMA is now a preferred supplier to several major international barge builders.

Upgraded design | The H-GRD is a robust and reliable valve, easy to disassemble and equipped with a special rotor for this application. TBMA recently introduced a new design featuring a direct in-line drive, resulting in a more compact installation, fewer parts, and even easier maintenance. This new design has been warmly received by barge manufacturers. One of them even installed it in the largest barge built to date, which includes 24 feed lines, each equipped with a dosing valve.

Upward pressure

The offshore location can sometimes lead to specific issues. In some cases, air and feed couldn’t exit through the valve and were blown back into the hopper. A TBMA technician traveled to Norway to inspect on-site at a barge. He discovered from the production data that the issue always occurred after maintenance on the feeding lines. It turned out that upward pressure caused the feed lines to fill with water, sometimes over lengths of 100 meters. After maintenance, the feed system was restarted at full capacity. However, the blower downstream of the valve was not powerful enough to push the water out of the line, normalise pressure, and convey the feed. Additionally, the pipes were sometimes still damp, causing the pellets to stick and clog the lines.

TBMA has been designing and delivering pneumatic conveying systems for over 55 years, and that expertise was decisive in this case. The valve malfunction was just a symptom—the real issue lay in the system. The solution was simple but effective: after maintenance, run the blower first to empty and dry the lines and stabilise the pressure before starting the feed dosing via the valve. The system has worked perfectly since, resulting in a satisfied customer.

Supply chain

TBMA valves have long been used in the production of fish feed (and its raw materials) and for conveying it on barges. The lesser-known link in the chain is the feed supply to the barges. Recently, TBMA was approached by a builder of such supply ships to help develop a new method for transporting feed and to offer large rotary valves.

Conditions for transferring feed at sea are at another level: water, wind, currents, and waves all come into play. Additionally, large volumes (up to 100 tons/hour) of fish feed need to be transferred from one ship to another as quickly as possible. It's a challenge TBMA takes on with great enthusiasm! After all, it would mean TBMA valves could serve the entire aquafeed chain, and that’s something the Dutch SME is quite proud of.

Aquaculture visualised

Photo 1: Salmon are farmed in large numbers in open-sea fish pens.

Photo 2: Top view open-sea fish pens.

Photo 3: Barge builder GroAqua recently built the largest feed barge ever. It contains 24 feeding lines, each with the newest TBMA rotary valve.

Photo 4: The feed that the salmon gets has a semi-airy pellet form. Because it is greasy and must absolutely remain intact, its transport is not easy.