Container rotary valve skids

Transporting bulk goods in (lined) containers simplifies transport via road or water and is an excellent way to save on handling costs and reduce packaging material. TBMA offers various solutions for the Value Added Logistics (VAL) sector, including mobile, dust-proof rotary valve skids for either loading or unloading lined containers.

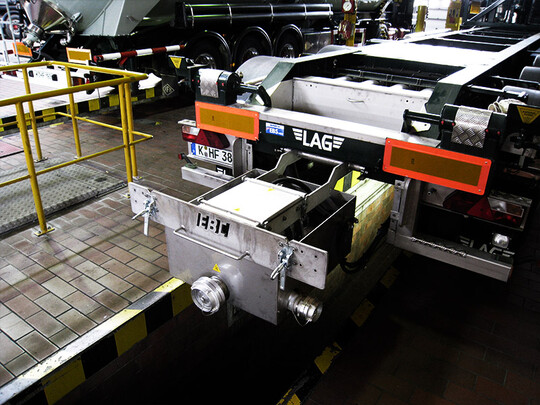

Bulk truck discharging

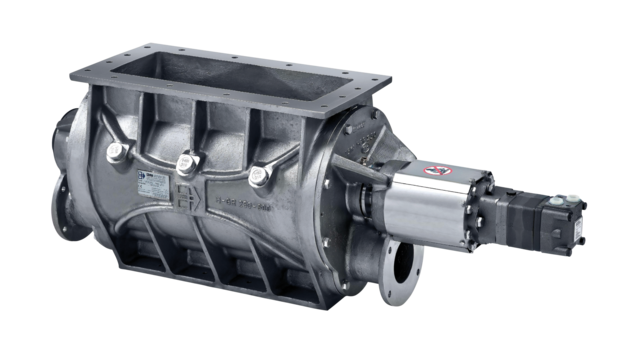

The EBC-by-TBMA bulk truck discharging solutions are most known as chassis mounted, extractable skids with a built-in rotary valve. This construction allows for quick and efficient unloading of a lined container: the receiving party only has to connect a blower and a conveying line and the discharging can start. Alternatively, the rotary valves can also be supplied as a stand-alone discharging unit mounted on a mobile frame.

TBMA has acquired the Danish company Eriksen Bulk Conveyor ApS (EBC ApS) as per October 2024. The EBC rotary valves and adjacent components have been integrated into the TBMA product range.

Lined containers

Reducing logistics and handling costs is of great importance for many companies. Transporting bulk goods in lined containers simplifies transport (via road or water) and is an excellent way to save on handling costs and packaging material.

The producer of the bulk material loads the product in a standard 20- or 40-foot container with an inner liner. The receiving party empties the container, removes the liner, and returns the container to the depot. TBMA supplies complete, mobile rotary valve skids for either loading or unloading lined containers. When necessary, we can also offer special, extended container valves for these applications. An additional advantage is that both systems – loading and unloading – can be operated by a single person.

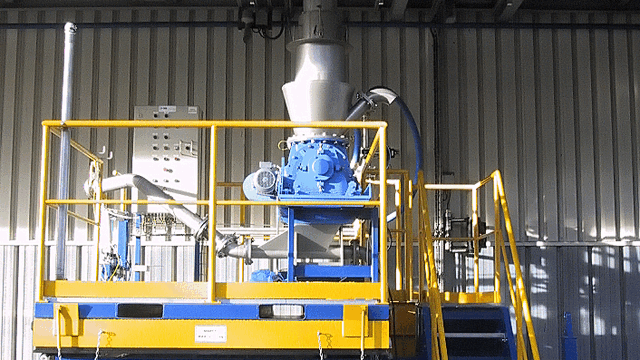

Lined containers - loading

In the value added logistics industry, bulk materials stored in silos are often reloaded directly into bulk trucks or lined containers. When loading into bulk trucks, gravity and a loading chute will usually do the trick. However, in the case of lined containers you need to blow the product into the container and at the same time make sure that the air can escape and is filtered, in order to retrieve any product that comes with it.

For loading these containers, TBMA supplies a mobile, height-adjustable platform with a filling unit including a special rotary valve, blower unit, cooler, blowpipe, and filter unit. The mobile unit is positioned under the silo and docked, using e.g. a loading chute. The container is then placed in front of the unit and the blowpipe can be slid into the liner. The container can thus be filled with a capacity of 20 to 30 tons per hour. The escaping air is guided through the filter unit and the intercepted product is returned into the filling line. This additional feature is necessary when handling powders or dusty products, such as pellets for animal feed. For most plastic granules the filter unit is not required.

Lined containers - unloading

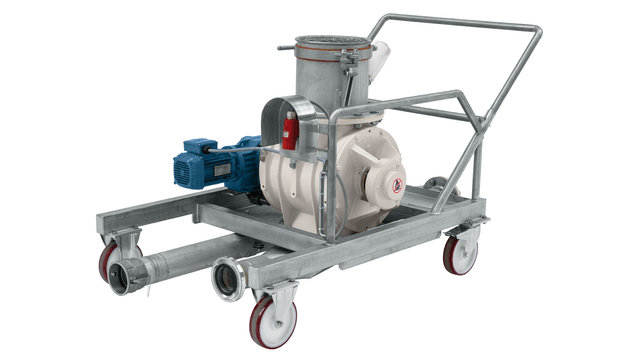

For unloading lined containers, we offer several mobile, dust-proof solutions, including a skid with a standard drop-through rotary valve and a dropout box/venturi adapter or a unit with a special, extended container blow-through rotary valve. Both systems are extremely flexible and can be quickly connected to a lined container at the inlet of the valve and a conveying line at the outlet(s).

When handling dusty products, the air leakage is returned into the liner. Due to its size, the liner will function like a cyclone, causing most of the dust to settle and once more be conveyed out of the liner back into the valve. The finer dust particles will be captured by a small filter unit. In the case of plastic granules, the latter is mostly sufficient.

The release time for a 20-foot container using a rotary valve is between 60 and 90 minutes, depending on the running characteristics of the product.