Feeders | gravimetric

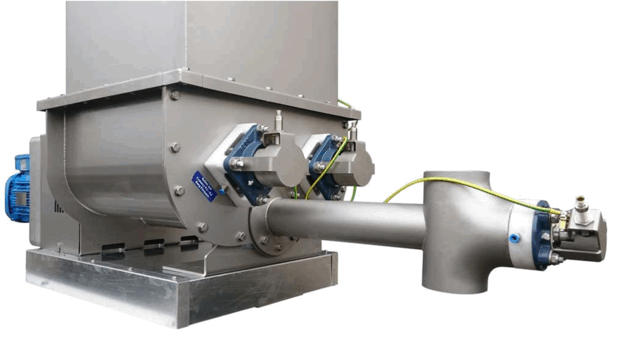

Feeders equipped with added gravimetric control provide effective monitoring of the dosed product flow and allow for continuous adjustment of the flow rate.

Gravimetric control

In gravimetric dosing, the dosing unit is equipped with a buffer, and the entire assembly is placed on (standard) load cells. During dosing, the weight loss per unit of time is continuously monitored and converted into the actual flow rate. This is compared with the desired flow, and the motor speed is adjusted if necessary.

When the hopper reaches the preset minimum level, the unit is refilled manually or automatically. During refilling, dosing continues volumetrically. After refilling, the control system waits until a continuous weight loss is detected again, at which point the regulation restarts.

Standard load cells and a standard Siemens PLC are used for this purpose. This eliminates the need for expensive replacement parts and ensures their availability. The PLC is equipped with proprietary software, developed based on years of experience. Additionally, a Profinet connection is used as standard, allowing easy integration into the central control system. Optional alternative connections can also be supplied.

For more information: sales@tbma.com (NL) or sales@tbma.be (BE)