How to process | Bentonite

Handling bentonite isn’t simple – and that’s exactly where the right rotary valve makes the difference.

Bentonite processing with rotary valves

Bentonite is a fine, abrasive material that can swell, cake, and absorb moisture, making it difficult to handle in industrial processes. Reliable bentonite processing depends heavily on selecting the right rotary valve for feeding, metering, and airlock applications.

Well-designed rotary valves ensure consistent material flow, protect downstream equipment, and reduce unplanned downtime.

Why bentonite is difficult to handle

Bentonite presents several processing challenges:

- Fine particle size increases the risk of air leakage and inconsistent feeding

- Abrasive nature accelerates wear on rotors and housings

- Moisture sensitivity causes swelling, caking, and material buildup

- Variable flow behavior impacts process stability and efficiency

Standard rotary valves often fail under these conditions.

What makes a rotary valve suitable for bentonite?

Rotary valves designed for bentonite focus on durability, sealing, and flow control:

- Hardened or wear-resistant rotors to withstand abrasion

- Abrasion-resistant housings for extended service life

- Tight clearances to minimize air leakage

- Moisture-aware sealing solutions to prevent caking and buildup

- Proper venting options for pneumatic conveying systems

Correct valve configuration is critical for applications such as pneumatic conveying, dust collection, and controlled metering.

Benefits of proper bentonite flow control

When bentonite flows consistently through the process:

- Equipment efficiency improves

- Maintenance frequency is reduced

- Downtime is minimized

- Overall equipment life is extended

Choosing the right rotary valve directly impacts process reliability, not just component performance.

Choosing the right valve

Choosing the right rotary valve isn’t just a component decision – it’s a process reliability decision. We know the challenges – and we’re here to help you choose the right solution.

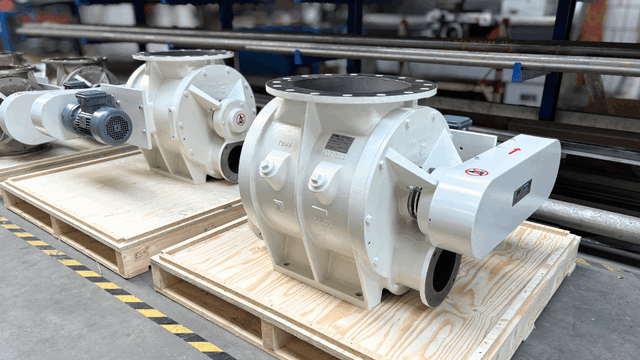

Image: H-GR350/4TCO blowing seal

- Application: handling bentonite, outdoor usage

- Capacity: 24 t/h

- Execution: cast iron internally tungsten carbide plated body, stainless steel rotor with adjustable and replaceable blades