Special-duty valves

In most cases, a smart choice of type and design will help you find the right rotary valve from our standard program. For special or highly critical applications, we will gladly use our experience and knowledge of systems and processes to find the right solution for your process.

What challenge can we help you with?

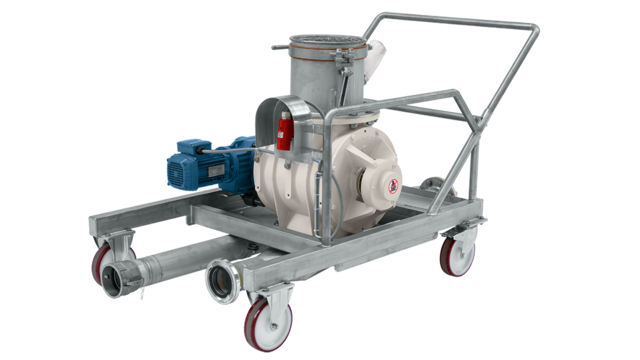

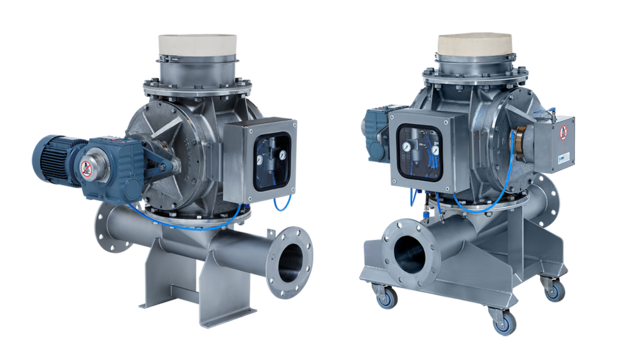

Bulk truck discharging rotary valve

The EBC-by-TBMA bulk truck discharging solutions are most known as chassis mounted, extractable skids with a built-in rotary valve. This construction allows for quick and efficient unloading of a lined container: the receiving party only has to connect a blower and a conveying line and the discharging can start. Alternatively, the rotary valves can also be supplied as a stand-alone discharging unit mounted on a mobile frame.

TBMA has acquired the Danish company Eriksen Bulk Conveyor ApS (EBC ApS) as per October 2024. The EBC rotary valves and adjacent components have been integrated into the TBMA product range.

Lined containers

Reducing logistics and handling costs is of great importance for many companies. Transporting bulk goods in lined containers simplifies transport (via road or water) and is an excellent way to save on handling costs and packaging material.

The producer of the bulk material loads the product in a standard 20- or 40-foot container with an inner liner. The receiving party empties the container, removes the liner, and returns the container to the depot. TBMA supplies complete, mobile rotary valve skids for either loading or unloading lined containers. When necessary, we can also offer special, extended container valves for these applications. An additional advantage is that both systems – loading and unloading – can be operated by a single person.

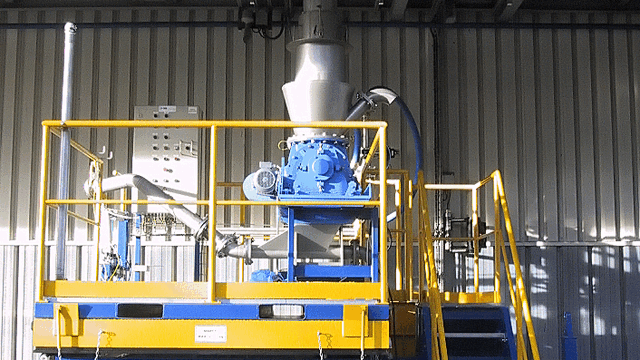

Lined containers - loading

In the value added logistics industry, bulk materials stored in silos are often reloaded directly into bulk trucks or lined containers. When loading into bulk trucks, gravity and a loading chute will usually do the trick. However, in the case of lined containers you need to blow the product into the container and at the same time make sure that the air can escape and is filtered, in order to retrieve any product that comes with it.

For loading these containers, TBMA supplies a mobile, height-adjustable platform with a filling unit including a special rotary valve, blower unit, cooler, blowpipe, and filter unit. The mobile unit is positioned under the silo and docked, using e.g. a loading chute. The container is then placed in front of the unit and the blowpipe can be slid into the liner. The container can thus be filled with a capacity of 20 to 30 tons per hour. The escaping air is guided through the filter unit and the intercepted product is returned into the filling line. This additional feature is necessary when handling powders or dusty products, such as pellets for animal feed. For most plastic granules the filter unit is not required.

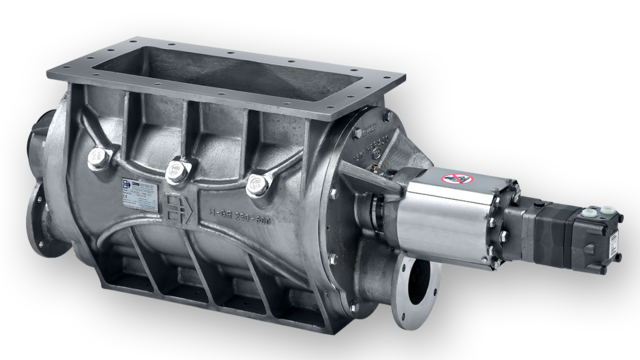

Lined containers - unloading

For unloading lined containers, we offer several mobile, dust-proof solutions, including a skid with a standard drop-through rotary valve and a dropout box/venturi adapter or a unit with a special, extended container blow-through rotary valve. Both systems are extremely flexible and can be quickly connected to a lined container at the inlet of the valve and a conveying line at the outlet(s).

When handling dusty products, the air leakage is returned into the liner. Due to its size, the liner will function like a cyclone, causing most of the dust to settle and once more be conveyed out of the liner back into the valve. The finer dust particles will be captured by a small filter unit. In the case of plastic granules, the latter is mostly sufficient.

The release time for a 20-foot container using a rotary valve is between 60 and 90 minutes, depending on the running characteristics of the product.

Guarded air lock seal

Lactose is a milk derivative that is lubricating and grows strongly during processing. TBMA has developed rotary valves for this purpose with a special labyrinth shaft seal including an air monitoring system. This system detects any problems early, so that preventive maintenance can prevent production downtime.

The valves are equipped with a special rotor with minimal friction surfaces. Critical valves can also be of mobile design to enable a quick change and wet cleaning outside the production environment.

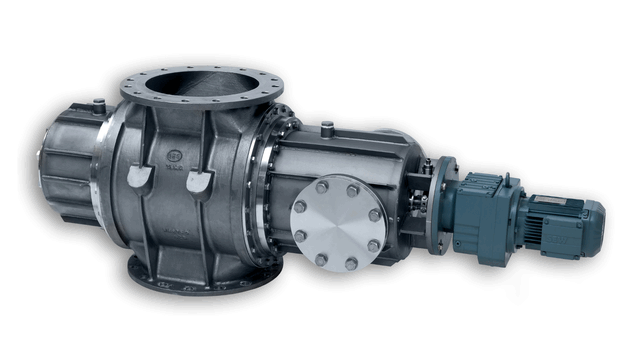

Pressure chamber

This special-duty H-AR drop-through valve is suitable for all critical processes involving toxic gases and high process pressures. The smart and safe valve was developed for a production process for titanium dioxide using chlorine gas and has been operating satisfactorily for twenty years.

It is made from a very special alloy of (among others) nickel, chrome, molybdenum and niobium. This material has excellent resistance to various corrosive media - including chlorine gas - and is resistant to high pressure.

By applying a pressure within the extra lantern covers that is more than twice as high as the system pressure, a pressure chamber is created, as it were. In case the seals of the rotor start to leak, the overpressure ensures that no toxic gas can leak out from the valve.

See also article Safe rotary valve for toxic process gasses

Steam tracing

Maintaining the process temperature is of great importance for some processes. A ‘cold bridge’ can cause condensation, which means that certain products can grow. The standard method to prevent this problem is to heat the process equipment. Rotating airlocks are a tricky component in this regard: the shape and the narrow clearances in the valve make even heating very difficult.

For this, TBMA has developed a double-walled drop-through valve with a steam jacket. The steam in the jacket ensures continuous, uniform heating of both the body, the covers and the rotor, thereby preventing the formation of condensation.

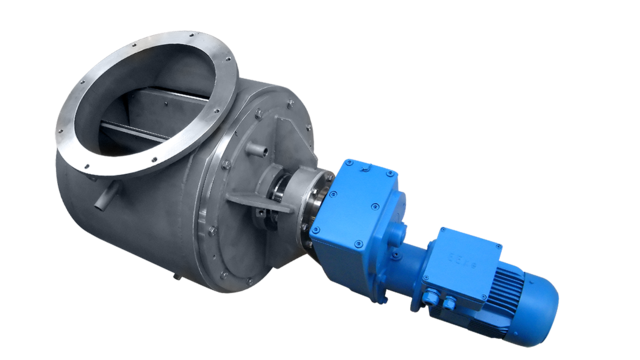

Inspection hatches

TBMA has developed this large fall-through valve (inlet 600) especially for heavy, non-hygienic applications where frequent internal inspection is required.

Important factors for quick and regular access to the interior of a rotating valve are ease of use, safety, ergonomics and reliability. For this TBMA has equipped the lock with inspection hatches in the body and the covers.

More info

Brochure Rotary Valves View

Industries

Curious when to use the above system? Have a look at our selection of industries for a suitable application of this system and of our other products.

Looking for a more specific industry and/or application? We are happy to take on the challenge! Contact us at sales@tbma.com.

TBMA are specialists in the design and supply of components and systems for bulk solids handling. Our extensive range of high quality processing equipment is suitable for handling powders and granules with proven reliability in practice in a variety of processing industries. The highly qualified and experienced TBMA staff are well able to translate your requirements into the right execution and application of our components. We also offer the design and execution of complete projects, thus providing you with an efficient, reliable and sustainable solution for your process.

How can we help you?